What the heck is heat treating?

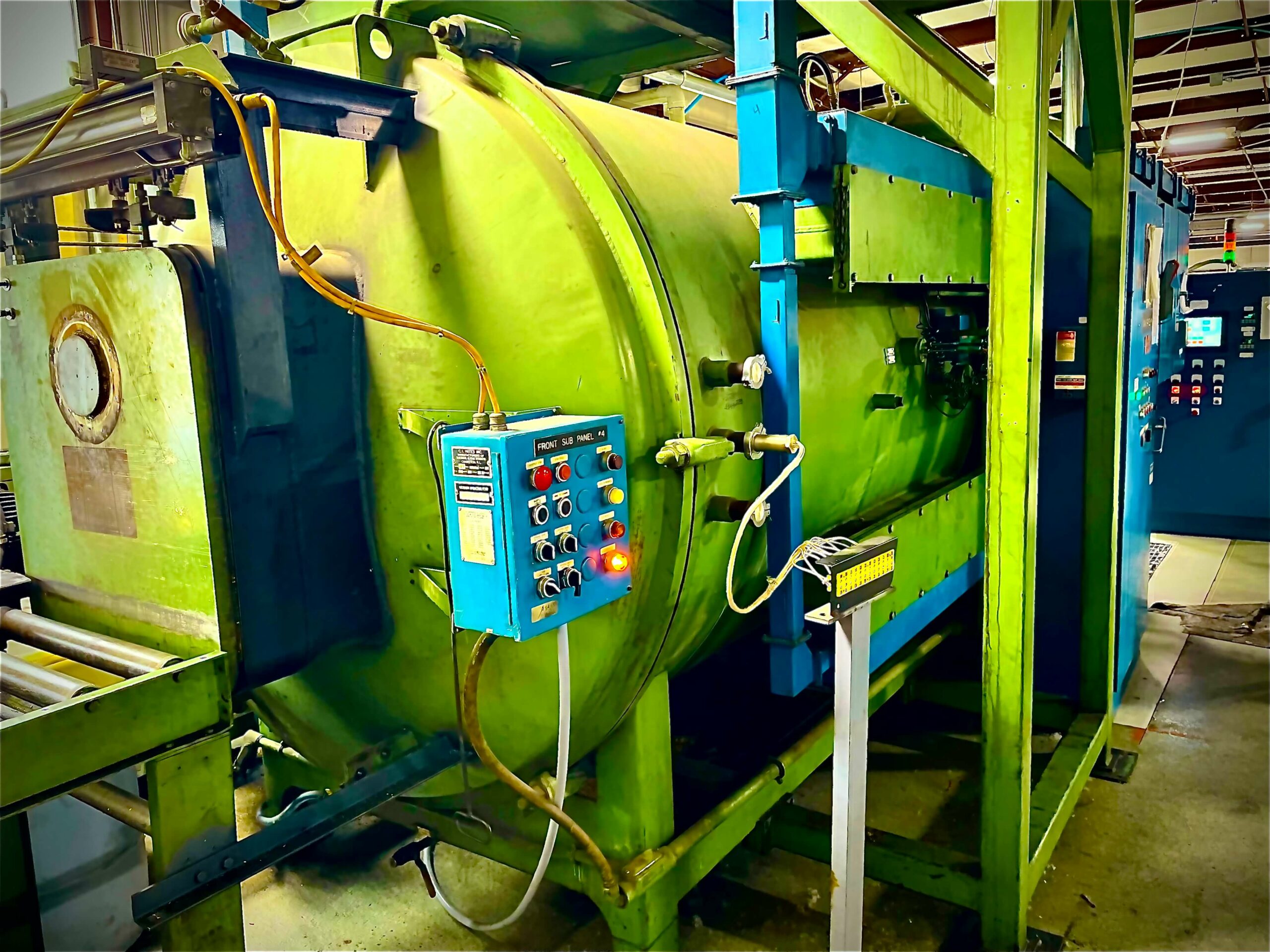

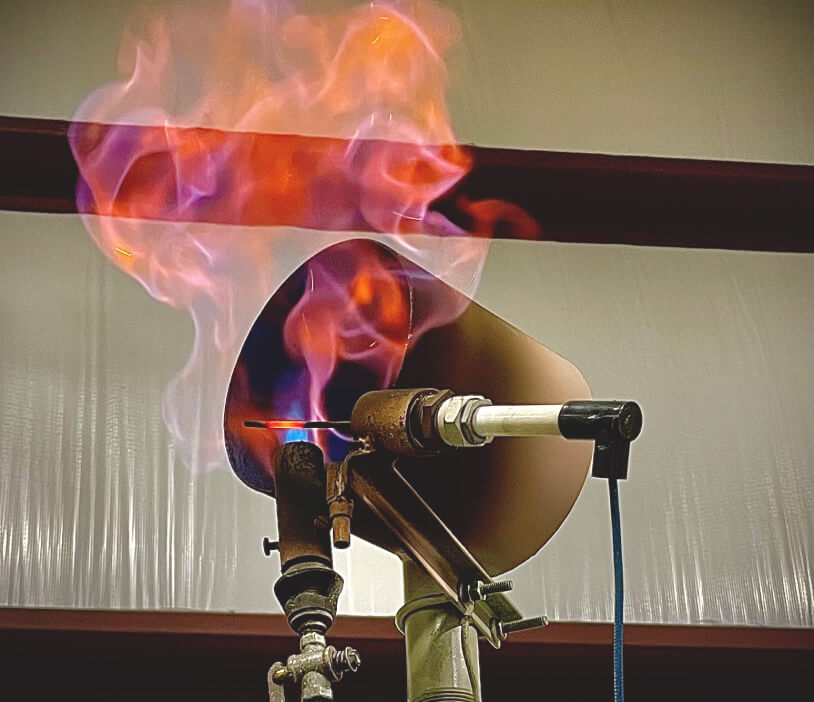

Heat treating is a little known, but very important, step of almost every critical manufacturing supply chain. From jet engine components to vehicle transmission gears to the feet of a step ladder, heat treating adds value to metal parts by improving their properties (such as hardness, strength or ductility) to last in the applications they are designed for. Without heat treating, many products simply wouldn’t exist today, yet, it remains largely in the shadows of the overall manufacturing process. We invite you to explore the pages of the services that we offer. In addition to providing best-in-class customer service and fast turnaround times, we want you to know what happens when you send your critical parts to your heat treating supplier. At times, it can seem like a “black box” where parts go and return having been magically transformed. The truth is, it’s much more complex and scientific than that. And, if you don’t find all the information that you’re looking for, hit that Contact Us link and send us a message. We’ll get back to you in 24 hours or less.

These Are The Services That We Offer

Contact DMT to Learn What We Can Do For You

At Darby Metal Treating we are happy to help. Give us a call or send us a message by using one of the buttons below!

Need Machining as well?

Our sister company, TMD Machining, is a precision machine shop, so much so, that they specialize in aerospace solenoid valves. If you’re looking for a high quality machine shop, check out TMD.