Not all heat treating processes are for hardening…

Annealing is a broad term that encompasses several different sub-processes such as: solution annealing, isothermal annealing, full annealing, sub-critical annealing and more. Unlike other common heat treating processes, annealing is a process typically used to soften or reduce the hardness of various materials, or otherwise prepare their internal structure for further processing. This is achieved by first heating the material to very high temperatures (dependent upon material but anywhere from 1500 to 1900°F or more), followed by some sort of controlled cooling cycle (i.e. 100°F per hour). The primary differences in the various types of annealing processes are mainly dependent upon both or either of the heating temperature and rates of cooling.

Normalizing is a process used to achieve a particular type of microstructure, mostly the grain structure of the metal, after forming processes such as forging, casting or hot rolling. The normalizing process typically heats the material to a temperature similar to the hardening temperature, held for a period of time, followed by cooling in air.

Advantages

Annealing:

- Allows for easier machining of metal prior to hardening steps.

- Restores ductility and helps prevent potential cracking with future processing steps.

Normalizing:

- Restores a consistent microstructure after hot working to improve machinability and achieve a more predictable microstructure.

Disadvantages

Annealing:

- Slow cooling rates make for long furnace cycle times which can be costly.

Normalizing:

- Care must be taken with furnace atmosphere control to prevent decarburization (removal of carbon from steel surface).

Equipment Used

- Vacuum and atmosphere (air) style furnaces.

- Continuous belt hydrogen/nitrogen atmosphere furnaces.

- Working dimensions vary by furnace (up to 36″ W x 48″ L x 36″ H).

- Weight capacities vary by furnace (up to approximately 2,500 lbs.).

Materials (Alloys) Treated

- Almost all materials can be annealed (steel, brass, copper, aluminum, etc.).

- Normalizing is generally performed on carbon and low alloy steels.

Applications

The primary application for annealing is to correct the negative effects of work hardening (drawing, cold forming, etc.) and restoration of ductility to the material, while the primary application of normalizing is a more consistent microstructure.

Industries

Aerospace, automotive, industrial, power generation, marine, construction, mining, firearms, other defense industries.

Specifications

- AMS2759/1, AMS2759/2, AMS2759/3, AMS2759/4, AMS2759/5, AMS2761.

- OEMs and Tier 1 suppliers generally create their own specifications for annealing and normalizing.

Contact DMT to Learn What We Can Do For You

At Darby Metal Treating we are happy to help. Give us a call or send us a message by using one of the buttons below!

Need Machining as well?

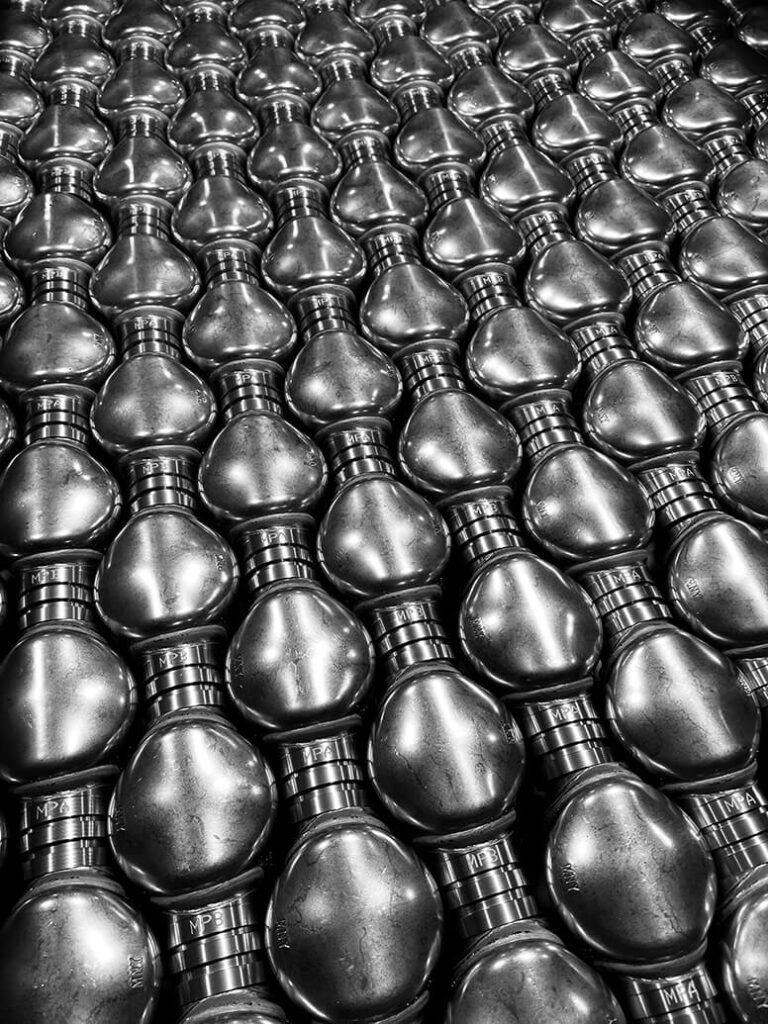

Our sister company, TMD Machining, is a precision machine shop, so much so, that they specialize in aerospace solenoid valves. If you’re looking for a high quality machine shop, check out TMD.