When you need hardness and strength throughout…

Neutral hardening is a heat treatment process used to increase the hardness and strength of various metals, including steel. This process involves heating the metal to a specific temperature (typically around 1500°F, although 400 series stainless is typically 1800 – 1925°F) and then rapidly cooling it in a quenching medium, such as oil, water, or gas. The objective of neutral hardening is to achieve a uniform and consistent hardness throughout the metals’ entire cross-section. After quenching, the material is at or near its highest hardenability, which also means that it is quite brittle. A secondary process called tempering must be performed, which is heating to a lower temperature, to lower the hardness from this brittle peak and restore some ductility to the steel.

Neutral hardening is one of the more common heat treating processes, so much so, that it has pseudonyms known as: quench and temper, direct hardening, hardening, and oil hardening.

Advantages

- Increases the hardness and strength of steel, while maintaining a good ductility level.

- Improves durability and wear resistance over steel that has not been treated.

- Imparts heat resistance, making it ideal for applications with high temperature environments.

Disadvantages

- Maximum achievable hardness is a function of the material chemistry.

- Distortion is possible with high temperature and rapid quenching processes. A final grind may be required.

Equipment Used

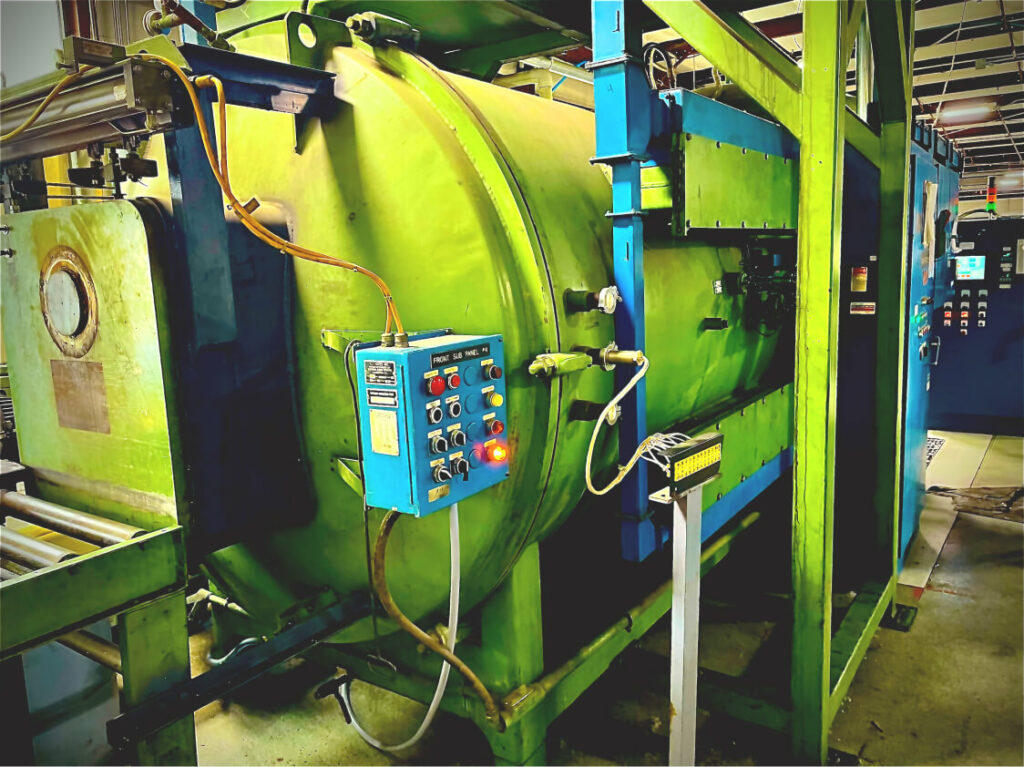

- Atmosphere batch integral oil quench furnace, vacuum gas (nitrogen) quenching furnace, vacuum oil quench furnace.

- Working dimensions vary by furnace (up to 36″ W x 48″ L x 36″ H).

- Weight capacities vary by furnace (up to approximately 2,500 lbs.).

Materials (Alloys) Treated

Alloy steels with enough hardenability to achieve the specified hardness, bearing steels, tool steels, and 400 series stainless steels.

Applications

Shafts, fasteners, tools, bearings, dies, and any component that will see a high load.

Industries

Aerospace, automotive, construction, mining, defense, firearms, power generation, machine builders, and several others.

Specifications

- AMS2759/1, AMS2759/2, AMS2759/5, AMS2761.

- OEMs and Tier 1 suppliers generally create their own specifications for neutral hardening.

Contact DMT to Learn What We Can Do For You

At Darby Metal Treating we are happy to help. Give us a call or send us a message by using one of the buttons below!

Need Machining as well?

Our sister company, TMD Machining, is a precision machine shop, so much so, that they specialize in aerospace solenoid valves. If you’re looking for a high quality machine shop, check out TMD.