Harden your stainless and exotic alloys with us!

This process is typically reserved for materials such as stainless steels, aluminum and nickel alloys including the aerospace exotics such as Inconel and Waspalloy, among others. Precipitation hardening and aging are similar processes, but they achieve different results for different materials. Both are generally performed in a highly uniform temperature controlled oven (i.e. +/- 10°F) to a set temperature for a set period of time at that temperature, before cooling in air to room temp.

Precipitation hardening for stainless steels is performed at or near the end of the manufacturing process, as it typically results in a significant increase in hardness by developing an alloy specific microstructure.

The aging process for nickel-based alloys can vary widely in temperature (1000 – 2080°F) and time and temperature are generally alloy specific. Aluminum aging is similar to a temper process for steels, where parts are heated in a highly uniform temperature controlled oven to a specific temperature and duration.

Advantages

- Increases toughness and yield strength of generally malleable materials.

- Allows for optimal properties for expensive materials.

- Achieves good high temperature strength for superalloys.

Disadvantages

- Size change, although predictable, can sometimes occur in the form of shrinkage (thousandths or ten-thousandths of an inch) and must be accounted for during part design.

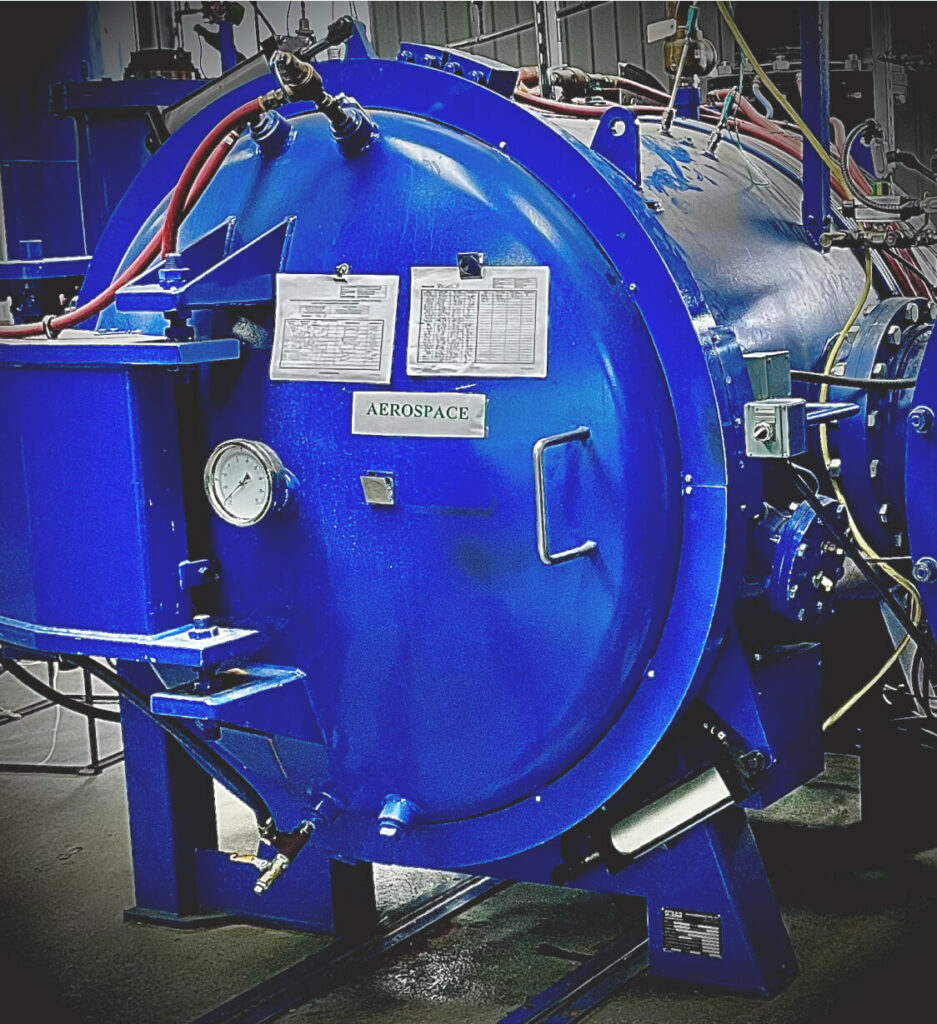

Equipment Used

- Vacuum and atmosphere (air) style furnaces.

- Working dimensions vary by furnace (up to 36″ W x 48″ L x 36″ H).

- Weight capacities vary by furnace (up to approximately 2,500 lbs.).

Materials (Alloys) Treated

- Certain stainless steels, nickel-based alloys, and aluminum alloys.

- DMT can process bars up to 6′ in length.

Applications

Airplane engine, wing, and body components, space exploration vehicles and instruments, high-tech defense applications, food and beverage equipment components, and select medical uses.

Industries

Aerospace, defense, food and beverage, medical, and other high-tech industries.

Specifications

- AMS2759/3, AMS2761.

Contact DMT to Learn What We Can Do For You

At Darby Metal Treating we are happy to help. Give us a call or send us a message by using one of the buttons below!

Need Machining as well?

Our sister company, TMD Machining, is a precision machine shop, so much so, that they specialize in aerospace solenoid valves. If you’re looking for a high quality machine shop, check out TMD.