Where parts that are stressed out come to relax…

Stress relieving is a low temperature process designed to use heat to draw out any stresses that have been induced into the material structure via cold working, such as machining, drawing, stamping, and other deformation processes. Generally, a part that has been stress relieved can then be further worked, with an increase in dimensional stability, and be ready for the final heat treating operation to be performed, such as carburizing or nitriding. Relieving stresses can also prevent future part failures due to stress cracking and the like. The process for stress relieving involves heating the parts to a particular temperature (1100 – 1250°F) and holding until the middle of the widest cross section reaches that temperature, and then a gradual cooling to room temperature.

Advantages

- Relieves stresses in the material before they show up at a higher temperature heat treating process.

- Relatively low cost way to save yourself dimensional problems later.

- Typically shorter furnace cycles, keeping costs lower.

Disadvantages

- Does add an additional processing step in the overall process to manufacture parts.

- Atmosphere furnaces can sometimes cause scale or discolor parts depending on temperature required.

Equipment Used

- Vacuum and atmosphere (air) style furnaces.

- Working dimensions vary by furnace (up to 36″ W x 72″ L x 30″ H).

- Weight capacities vary by furnace (up to approximately 3,000 lbs.).

Materials (Alloys) Treated

Steels, alloys, and irons.

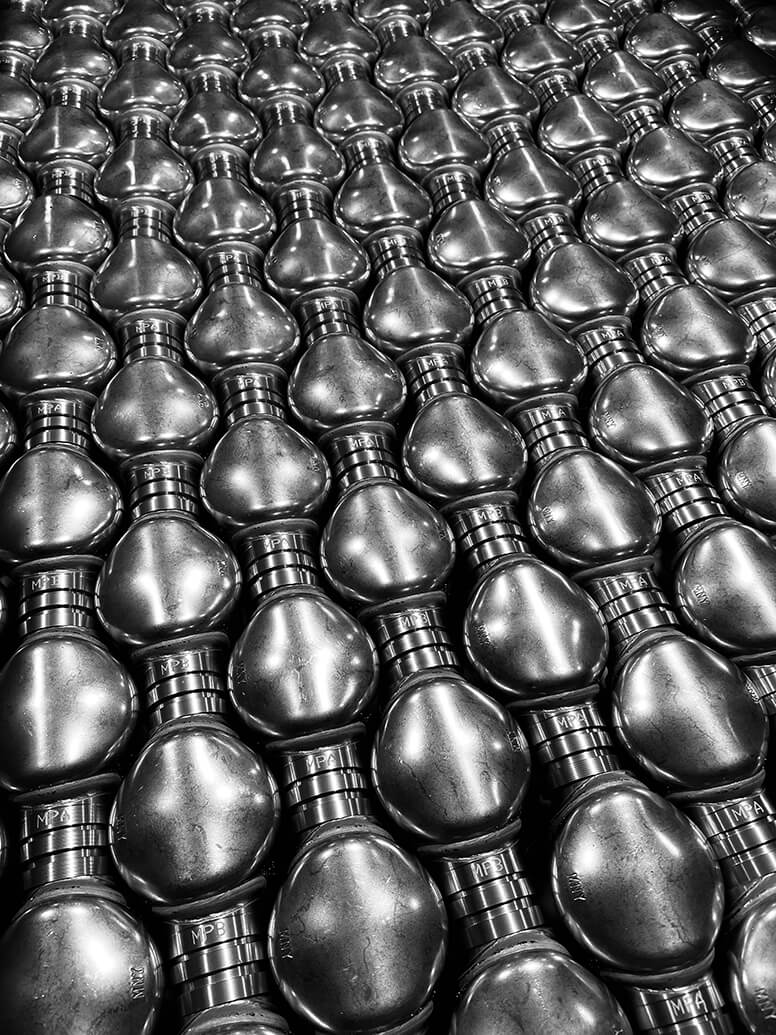

Applications

Any part that has received stresses from prior working such as forging, machining, stamping, or other cold working processes that impact the material.

Industries

Any industry using metal parts where forming processes cause stress can benefit from the stress relieving process.

Specifications

- AMS2759/11.

- Customer developed specification, if any, generally applies.

Contact DMT to Learn What We Can Do For You

At Darby Metal Treating we are happy to help. Give us a call or send us a message by using one of the buttons below!

Need Machining as well?

Our sister company, TMD Machining, is a precision machine shop, so much so, that they specialize in aerospace solenoid valves. If you’re looking for a high quality machine shop, check out TMD.